Natural stones and rocks have long since moved beyond the category of just finishing or ballast materials. Thanks to new technologies and chemical processes, classic stones such as basalt or granite are highly processed to produce artificial stone structures that have the durability and hardness of rock.

What is the mineral basalt

From the point of view of chemistry and mineralogy, natural material basalt is a complex structure in which crystalline formations and fine-grained inclusions of magnetite, complex silicates and metal oxides are intertwined. Basalt rock is of igneous origin, so its structure is more reminiscent of a complex mixture of amorphous volcanic glass, micron-sized crystals of feldspar, quartz, carbonates, and sulfide ores.

Basalt stone is easy to distinguish from other volcanic rocks, primarily due to its black, smoky black, greenish color. This stone is widely used in construction and the production of special materials for the chemical industry due to a number of specific properties:

- The material is very heavy and hard, the density of basalt rock can vary from 2.5 to 3 kg per dm 3, high hardness provides good resistance to abrasion, including under the influence of abrasives and water flows.

- The high melting point makes it possible in some cases to use rocks that are included in basalt to produce fire-resistant and refractory materials.

Important ! The simplest use is cutting basalt masses into facing stones and slabs. Due to the specific natural color of the rock, black or black-green finishes are widely used for cladding the walls of basements and porches.

Main directions of application of basalt

The most irrational way is to use basalt as ballast, crushed stone for road construction, filler for concrete castings, and sealing foundations. In some deposits, basalt stone has a relatively high water absorption coefficient, due to which screenings from such stone can be used to make exceptionally strong concrete foundations, walls, arches, and load-bearing columns.

Products of deep processing of basalt

The most well-known materials from basalt, obtained by melting the rock, are heat insulators, various brands of fiber material, and felt. Mineral fibers from basalt rock are very resistant to high temperatures and open flames. For example, a heat-insulating mat made of basalt fiber with a thickness of only 5 cm can withstand direct heating of a gas burner without destruction or burnout, while the temperature on the back side of the heat insulator does not rise above 50 o C.

In addition, basalt fiber does not give sharp chips, like fiberglass and glass wool, so it is safer for human skin, and any dust from basalt insulation is easily removed with water. However, when handling any basalt heat insulators, it is necessary to use respirators and safety glasses. The fiber material, several microns thick, produces large amounts of dust, which has a pronounced irritating effect. After finishing work, you must thoroughly wash your face, hands and other exposed areas of the body to get rid of basalt dust, which easily penetrates even through protective gloves.

Basalt felt is considered the most suitable and durable material for arranging protection and thermal insulation of chimneys, chimneys, fireboxes and stoves. Previously, asbestos fiber was used for similar purposes, but was abandoned in favor of basalt. Due to the high melting point of basalt, the production of fiber requires significant costs, so thermal insulation based on it has a relatively high price.

Remelting basalt rock not only produces fiber for the production of heat and thermal insulation; a similar method of high-temperature melt casting produces:

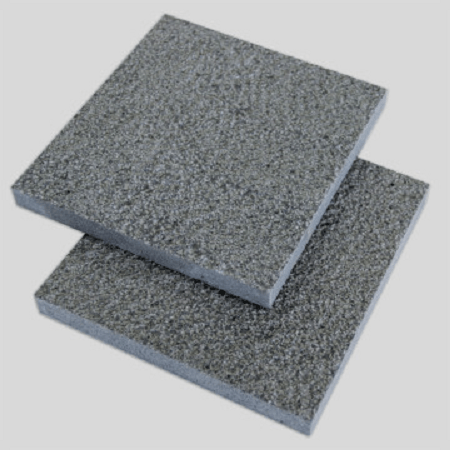

- Shaped parts and elements, tiles, floor coverings of non-standard shapes, intended for installation in places with high levels of human traffic. Due to their high hardness and wear resistance, the service life of such coatings significantly exceeds the wear parameters of clinker tiles, various sintered materials made of ceramics, dolomites, marble, calcite and other types of decorative stone and rock.

- The high density of basalt stone makes it possible to cast from the melt a specific type of product for high-voltage electrical networks. Insulators based on basalt rock have dielectric characteristics significantly higher than ceramic or glass ones. But not all types of basalt stone have similar properties; rock with an exceptionally high density, up to 3 tons per cubic meter, is suitable as a raw material. Such rock has to be mined from a depth of at least 70 meters in the mine.

- In addition to mechanical properties, products made from fused basalt are highly resistant to alkalis and acids at high temperatures, so shaped castings are often made from basalt for the construction of various types of apparatus, product pipelines, and containers in the chemical industry.

Finishing decorative forms of basalt

In addition to industrial use, basalt is increasingly used as a decorative stone due to its black with shades of gray, smoky, and sometimes greenish color. The most famous type of basalt decor is considered to be Italian-made facing tiles. Basalt tiles of a specific texture with a beautiful pattern can cost the same as marble or marble-like limestone trim.

Recently, finishing materials made from natural basalt stone with a specific smoky shade of the surface have appeared on the market. Thanks to its characteristic texture, natural stone from China is in increasing demand in the decoration of stairs and the creation of monuments, sculptures, and cladding of fountains. Cheaper varieties of basalt stone are used to build decorative fences, columns, entrance lobbies, and verandas. Increasingly, basalt stone is used as a material for the construction of monuments, steles, elements of tombstones and crypts.

High abrasion resistance makes it possible to use basalt in the form of paving stones for paving pedestrian areas and roadways. Moreover, the service life of such a coating can reach tens of years. In addition to paving stones, cast slabs are used, which in some cases successfully replace the finishing of stairs and steps made of porcelain stoneware, natural granite, gabbro and more expensive finishing materials.

Conclusion

Despite all the advantages of basalt, it is not recommended to use it for interior decoration, since this rock, like other heavy rocks of igneous origin, may have an increased background radiation. Therefore, careful testing and monitoring of the radioactivity level of this finishing material is required before its use.

The statement that basalt is the ruler of the Universe is very close to the truth. Why? This amazing natural stone exists not only on planet Earth; its deposits are widespread on Mars, the Moon, Venus and other planets.

The article gives general characteristics basalt, its properties, composition and areas of application are presented.

General information about basalt

It is believed that the name “basalt” comes from the Greek word translated as “base” or “foundation”. In the modern sense, “basal” means “lower”. It turns out that basalt is the base rock on which everything else rests.

There are other versions. The word "basal" in one of the African dialects means "boiling". Ethiopians believe that this is a mineral that first went through a boiling process in the crater of a volcano, and then poured out onto the earth's surface. And this version is close to the truth.

Basalt exhibits the properties of volcanic rock as often as the qualities of the base of continental plates. It is quite widespread throughout the planet, but is more common in areas with obvious volcanic activity.

Spreading

Basalts are extrusive igneous rocks with a dense and fine-grained structure found in areas of volcanic eruptions. Young rock can be found in the vicinity of the Kuril and Kamchatka volcanoes. There are amazingly beautiful black and green-black basalts in the areas of Etna and Vesuvius. Nearly black natural rock erupts in Hawaii.

Scientists prize Australian basalts and stones on one of Canada's cliffs. The most ancient basalt monoliths have been preserved on this exotic continent. There is an extremely large amount of this rock in India. Here, the Hindustan tectonic plate, cutting deeply into the Eurasian plate, piled up sedimentary deposits in the form of the Himalayan mountains, thus turning out the lower basalt layers.

Basalt is an amazingly beautiful stone found in nature in a wide variety of shades. Basalts of West African origin have outstanding decorative properties. Moorish varieties are famous for their original colors: beautiful colored splashes on a dark green stone background. Although basalt, compared to other stones, is less frost-resistant, the demand for it is huge. It is quite widely used as a building material.

In China, twilight basalt has a gray tint. It is used both as a finishing material in construction and for paving roads. Siberian and Chinese basalts are considered the most durable and weather-resistant.

Externally, the stone does not look particularly remarkable. It consists largely of augite and calcium feldspar. Usually this stone is black or dark gray in color, which is due to the content of dense, fine-grained rocks in it.

Theoretically, basalt is divided into 2 types: the first contains yellowish-greenish olivine crystals, the second contains original quartz inclusions.

Properties of natural stone

Basalt is a durable and heavy stone with attractive physical properties. It has high strength and good relative elasticity. Also positive is that any temperature changes do not affect it in any way. It is also resistant to both alkalis and acids, and practically does not absorb moisture.

There is another important advantage of basalt - it is resistant to corrosion, it has a complete absence of inductance and field conductivity when exposed to radio frequency energy. And the most important thing is that the material, being the purest product of the earth’s interior, is environmentally friendly.

Basalts are created at the tops of ash and lava flows. Their origin is volcanic, and the color variations of the stones directly depend on the shades and composition of the lava.

The rock mainly consists of pyroxene and plagioclase. Small crystals on basalt form when magma cools and solidifies. As a rule, this occurs on the surface of the earth's crust. Such formations are common in the process of spreading on the ocean floor, because upon contact with sea water, magma cools much more rapidly.

Basalt is the basis of oceanic crust, and large masses of it are produced above ocean hot spots. During a volcanic eruption, a huge amount of lava passes through the earth's crust and rises to its surface. This is how basalt stones - igneous rocks - are formed.

Use in treatment

Combining the elements of fire, air, earth and water, the stone accumulates and retains heat for a long time. Similar properties of basalt have found application in medicine. It has an excellent ability to thermally affect the body.

Since ancient times, basalt has been successfully used in oriental medicine; it is practiced in stone therapy (massage using hot volcanic stones). This technique helps strengthen immune system body. Basalts containing olivine are especially good in this regard. Under the influence of the heat of these stones (they heat up to 55 degrees), penetrating deep into the body up to four centimeters, the body relaxes, and this helps relieve stress.

Basalt in stone therapy, which is based on contrasts, plays the role of a hot stone, while marble is cold. This therapy helps rid the body of muscle spasms, kidney pain and osteochondrosis. An important condition of the Eastern technique is the use of stones in their natural form. The larger the stone, the more significant its effect on the body.

Hot basalt is also good in combination with natural essential oils, which has a great effect on the relaxation of the body. After each treatment session, it is recommended to clean the stones from the negative energy accumulated in them. They should be washed in clean water or placed in dry salt for a certain time. At the end of such procedures, the basalt should be laid out in a place illuminated by the sun to recharge them with energy.

Application

Basalt is a stone widely used in everyday human life. In recent years, basalt casting has become increasingly used, used for the manufacture of chemical equipment, acid-resistant pipes, etc.

The excellent aesthetic properties of strict noble stone are used to create large and small sculptural groups, jewelry and interior decorations. The solemn blackness of basalt combines perfectly with the shine of silver. Application in manufacturing jewelry lighter basalt is also found. Necklaces, bracelets, beads and belts made from polished basalt shapes make up amazingly beautiful sets.

Today furniture is also produced from cast basalt. Often in the design of local areas you can find stone details (columns, walkways, stairs, etc.) made of elegant basalt.

In conclusion, some interesting facts

Basalt is widely used today. What they don’t do with it! Modern manufacturers use this amazing material to produce tennis rackets, skateboards, snowboards, skis, revolutionary new acoustic basalt systems with excellent vibration perception, and much more. Surprisingly light and at the same time strong fabric is made from this natural stone.

Average chemical composition of basalt according to R. Daly (%): SiO 2 - 49.06; TiO 2 - 1.36; Al 2 O 3 - 15.70; Fe 2 O 3 - 5.38; FeO - 6.37; MgO - 6.17; CaO - 8.95; Na 2 O - 3.11; K 2 O - 1.52; MnO - 0.31; P2O5 - 0.45; H 2 O - 1.62. The SiO 2 content in basalt ranges from 44 to 53.5%. According to the chemical and mineral composition, olivine basalts unsaturated with silica (SiO 2 about 45%) and tholeiitic basalts without olivine or with an insignificant olivine content, weakly saturated with silica (SiO 2 about 50%) are distinguished.

The physical and mechanical properties of basalt are very different, which is explained by different porosity. Basaltic magmas, having low viscosity, are easily mobile and are characterized by a variety of occurrence forms (covers, flows, dikes, strata deposits). Basalt is characterized by columnar, less often spherical, individuality. Olivine basalts are known on the ocean floor, oceanic islands (Hawaii) and are widely developed in folded belts. Tholeiitic basalts occupy vast areas on platforms (trap formations of Siberia, South America, India). The rocks of the trap formation are associated with deposits of iron, nickel, platinum, and Iceland spar ores (Siberia). A deposit of native copper is known in the amygdaloidal basaltic porphyrites of the Lake Superior region in the USA.

Basalt density is 2520-2970 kg/m³. Porosity coefficient 0.6-19%, water absorption 0.15-10.2%, compressive strength 60-400 MPa, abrasion 1-20 kg/m², melting point 1100-1250°C, sometimes up to 1450°C, specific heat capacity 0.84 J/kg K at 0°C, Young's modulus (6.2-11.3) 10 4 MPa, shear modulus (2.75-3.46) 10 4 MPa, Poisson's ratio 0.20-0, 25. High strength of basalt and relatively low temperature melting led to its use as building stone and raw materials for stone casting and mineral wool. Basalt is widely used to produce crushed stone, road (side and paving stones) and facing stones, acid- and alkali-resistant material. Industry requirements for the quality of basalt as a raw material for crushed stone are the same as for other igneous rocks. To produce mineral wool, basalt is usually used in blending. It has been established that the melting point of the raw material should not exceed 1500°C, and the chemical composition of the melt is regulated by the following limits (%): SiO 2 - 34-45, Al 2 O 3 - 12-18, FeO up to 10, CaO - 22-30, MgO - 8-14, MnO - 1-3. Basalt casting materials have great chemical resistance, hardness and abrasion resistance, high dielectricity and are used in the form of floor and cladding slabs, pipeline linings, cyclones, and also as various insulators.

The physical and mechanical properties of basalts and basaltic andesites are very heterogeneous. This is due to the diversity of mineral composition, structure and texture of the rocks. Thus, basalts with a microcrystalline structure have specific gravity up to 3.3 T/m3, volumetric weight up to 3.0 T/m3, temporary compressive strength up to 5000 kg/cm2, while in porous basalts the compressive strength can be less than 200 kg/cm2. Ancient paleotype volcanic rocks are also characterized by great variability in strength and deformation properties, but in general they have higher values of these indicators. This is explained by the decrystallization of volcanic glass, the filling of pores with secondary minerals and other post-magmatic transformations of the erupted rocks. N.V. Ovsyannikov provides interesting data on the relationship between the strength of andesite-basalts and their composition, structure and porosity, which shows that the strength of andesite-basalts significantly depends on the mineralogical composition.

Olivine varieties have the greatest strength, and augite varieties have the least strength. The structure of the rock is no less important. Andesite-basalts of the same composition with a vitrophyre structure of the groundmass have significantly lower strength than rocks with an intersertal structure. Research by V.M. Ladygin and L.V. Shaumyan made it possible to establish that basalts of different petrochemical compositions and different structures have different physical and mechanical properties. The most durable are massive, unaltered porphyry basalts with microdiabase and microdolerite structures. Their strength averages 2000 kg/cm2, reaching in some cases 2800 kg/cm2 with a volumetric weight of 2.80 G/cm3. The dynamic modulus of elasticity of rocks in the massif is on average 690 103 kg/cm2. In amygdaloid basalts, the influence of the structural and mineralogical features of the rock is neutralized by the presence of amygdalae, the content of which reaches 15-30%. They are characterized by relatively low values of strength (1200 kg/cm2), elastic modulus (480-103 kg/cm2) and volumetric weight (2.66 G/cm3). It has been established that an increase in the content of denitrified glass to 10-15% reduces the strength of basalts by 10-20%; the presence of tonsils in an amount of 10-20% has the same effect. In weathered rock varieties, the strength decreases sharply. The degree of weathering of basaltic rocks and the thickness of the weathering crust generally depend on their age and climatic conditions.

Basalt, an analogue of gabbro, is the most common extrusive rock; depending on the conditions of formation, it has a glassy or cryptocrystalline structure. The color of basalt is dark gray to black. In terms of physical and mechanical properties, basalt is similar to gabbro, and even surpasses it in strength (Lszh reaches 500 MPa). Basalts are very hard, but brittle rocks, which makes them difficult to process.

Application of basalt

Practical use basalt building materials made from this stone are widely used in construction because they are characterized by: resistance to abrasion, resistance to alkalis and acids, excellent thermal insulation and noise absorption, strength, heat resistance and fire resistance, high dielectricity, durability, vapor permeability and, what not less important is environmental friendliness.

This mineral is used as a building stone, for the production of mineral wool, filler for concrete and stone casting. It is also used to make road and facing stones, crushed stone and acid-resistant powder. At the moment, facing slabs simultaneously serve as insulators for decorative purposes. Due to its resistance to weathering, basalt is well suited for finishing the exterior of buildings, as well as for casting outdoor sculptures.

The production of basalt and products based on it most often the production of basalt is a mining industry. Stone is extracted in special quarries and mines, on the basis of which various products are subsequently produced. In the form of basalt fiber, this mineral is used for insulation of buildings and roofs, in three-layer sandwich panels, insulation of low-temperature equipment units when extracting nitrogen and creating oxygen columns, for heat and sound insulation of pipelines, stoves, fireplaces and other braziers, power units and in general buildings and structures for any purpose. Molten basalt is used to create stair steps, shaped tiles and other building materials. Devices of arbitrary shapes are cast from it, including stands for batteries, as well as insulators for networks with different voltages. Powder from this material is used for the production of pressed reinforced products.

Common types of basalt differ from each other in various indicators, primarily such as color and structure. The most famous brand is the variety called “Basaltina”. This is a material of Italian origin, which is mined near the capital of this country and has been used mainly for architectural purposes since the times of Ancient Rome. Its strength is comparable to that of granite, and its decorative qualities are comparable to those of limestone. The stone retains its saturation for a long time after laying color palette. Therefore, its cost is often more than twice the price of other brands.

Another variety is Asian. It is distinguished by its dark gray color and reasonable price. It is widely used for design and architectural purposes.

Moorish green basalt has a rich dark green hue, with various inclusions present in it, which give the stone an original appearance while maintaining all physical and mechanical characteristics. Only the criteria for hardness and frost resistance are somewhat lower.

Twilight basalt is brought from China. It has a smoky gray or black color. It is recognized as the strongest and most wear- and frost-resistant among all varieties of this mineral. It is well protected from negative atmospheric influences.

The most famous products made from basalt: basalt-based insulation, basalt finishing tiles, basalt chimneys for fireplaces and stoves.

Charts

Fig.8 Lunar basalt: diagram

"Debye temperature of a chemical element (Q) - Concentration coefficient (K k)"

Fig.9 Lunar basalt: diagram

"Debye temperature of a chemical element (Q) - Content of a chemical element (C)"

Fig. 10 Basalt: diagram

"Atomic mass of a chemical element (M) - Content of a chemical element (C)"

Fig. 11 Lunar basalt: diagram

"Atom mass of a chemical element (M) - Concentration coefficient (K k)"

Fig. 12 Lunar basalt: diagram

"Distance to the inert gas of a chemical element (e) - Concentration coefficient (K k)"

Fig. 13 Lunar basalt: diagram

"Distance to inert gas of a chemical element (e) - Content of a chemical element (C)"

Appendix A

Appendix B

LITERATURE

1. Bondarenko S.V. Geochemical features of Lower Proterozoic quartzites in the central part of the South Pechenga zone./ S.V. Bondarenko, V.A. Shatrov, V.I. Sirotin // Geology and geoecology: research of young people. Materials of the XVI Conference of Young Scientists, dedicated to the memory of Corresponding Member. K.O. Briefly. Ed. acad. RAS Mitrofanova F.P. – Apatity, 2005. – 426 p.

2. Gumirov Sh.Sh. Modeling of the solid-phase diffusion process. /Collect.thesis. part. 15 Ross. conf. “Youth, science, culture.” - Obninsk: DNTO Intelligence of the Future, 2000. - pp. 112-113.

3. Gumirov Sh.V. Participation of the atomic impulse in biochemistry, coalification, mineralization. / Sh.V. Gumirov – High-tech technologies for the development and use of mineral resources: collection. scientific articles / Sib. state industrial University; under general editorship V.N.Fryanova. – Novokuznetsk, 2014.– p. 345-355.

4. Gumirov Sh.V. Modeling of solid-phase diffusion of elements to explain their differentiation in the lithosphere and ore genesis. – Natural and technical sciences, No. 1, 2008. – p. 183-188.

5. Gumirov Sh.V. Fundamentals of the theory of adaptation of inanimate objects and adaptive analysis in geology. /Sh.V. Gumirov - Novokuznetsk, media, 1993. - 409 p.

6. Gumirov Sh.V. Modeling the process of solid-phase diffusion of chemical elements to explain their differentiation in the lithosphere. / Sh.V.Gumirov, Sh.Sh. Gumirov // Bulletin of the Russian Academy of Natural Sciences (West Siberian Branch) Issue 5. Kemerovo, 2002 - pp. 273-282.

7. Konilov A.N. Petrology of “Frozen veins” in eclogites of the White Sea province on the Kola Peninsula. / A.N. Konilov, A.A. Shchipansky. // Physico-chemical factors of petro- and ore genesis: new frontiers. Mat. conf. dedicated 110 years old D.S. Korzhinsky. - M., 2009.- p. 198-203.

8. Lazko E.M. Thermobarogeochemistry and prediction of post-magmatic mineralization. / EAT. Lazko et al. // Thermobarochemical studies of mineral formation processes. - Novosibirsk: Science, 1988. - P. 136 - 149.

9. Medvedev V.Ya. The influence of shock decompression on the distribution of LIL and HFS elements in pyropes from kimberlites. / V.Ya. Medvedev, K.N. Egorov, L.A. Ivanova // Physico-chemical factors of petro- and ore genesis: new frontiers. Mat. conf. dedicated 110 years old D.S. Korzhinsky. - M., 2009.- p. 269-271.

10. Ovchinnikov L.N. Formation of ore deposits. / L.N. Ovchinnikov - M.: Nedra, 1988. - 255 p.

11. Rundqvist D.V. General principles construction of geological and genetic models of ore formations. T.1. / D.V. Rundkvist - Novosibirsk: Science, 1983. - P. 14 - 26.

12. Anand M. Petrology and geochemistry of LaPaz Icefield 02205: A new unique low-Ti mare-basalt meteorite. / M. Anand, Lawrence A. Taylor, Christine Floss, Clive R. Neal, Kentaro Terada, Shiho Tanikawa.

BASALT, a ceramic material with high mechanical, physical, electrical and chemical properties and obtained by thermal processing of rocks of the same name.

1. Basalt as a rock. Basalt, or rather basalts, are among the characteristic igneous (effusive) basic rocks of deep origin and young, mainly Tertiary, age. Basalt gained its wide popularity for the picturesque units it forms in the form of 6-sided (and sometimes 3- or 5-sided) prisms 3-4 m long with planes perpendicular to the faces (Fig. 1); it is also found in the form of flagstone natural stairs, shelled spherical units and other extremely picturesque rocks.

Basalt is a dark-colored rock, sometimes grayish-black, sometimes with a bluish tint; sometimes it is greenish or reddish. The very name “basalt” is of ancient origin and in the Ethiopian language means “dark”, “black”. This breed is very uniform in its fine structure. Dense and extremely hard, it has different cases grain size of different order. Coarse- and medium-grained varieties are called dolerites, fine-grained varieties are called anamesites, and very fine-grained varieties are called basalt itself. The difference in basalt texture with the same bulk composition is explained by the conditions of solidification of the erupted magma (cooling rate, pressure, etc.). The petrographic composition of basalt can vary significantly, but the minerals included in the basalt are replaced by petrographic equivalents, as a result of which basalt as a rock retains its habitus very stably. Under a microscope, basalt appears as a glassy groundmass (“basis”) with a microfluidic composition. The base contains numerous crystals of feldspar, olivine, magnetic iron ore and other less characteristic minerals. Depending on the content of mineral inclusions cemented by the base, basalts are distinguished: plagioclase, leucite, nepheline and melilite. Actually, the first ones are usually called basalt, that is, those containing calc-sodium feldspar, augite and olivine. Chemically, basalt is related to gabbro (G.) and diabase (D.). The bulk chemical analysis of plateau-forming basalt is characterized, according to Washington, by the following data:

Basalt is characterized by significant radioactivity: it contains from 0.46∙10 -3 to 1.52∙10 -3% thorium and from 0.77∙10 -10 to 1.69∙10 -10% radium. Less deep varieties of basalt are more acidic and gradually turn to dacites, trachytes, etc. According to the latest views, basalt is a material that forms the hard shell of the earth: under the continents it is 31 km thick, and under the oceans - from 6 km or more; this shell floats on a viscous-liquid underlying layer of basalt (“substrate”). Thus, it is assumed that basalt is found everywhere. As for the surface of the earth itself, outcrops of this rock are very numerous. Outside the USSR they are available: in the Auvergne, along the banks of the Rhine, in Bohemia, Scotland and Ireland, on the island of Iceland, in the Andes, on the Antilles, on the island of St. Helena and in various other places. There are many basalt deposits in the northern, western and southeastern parts of Mongolia. Within the USSR, basalt is distributed in the Caucasus and Transcaucasia, as well as in northern Siberia, in the river basin. Vitima. In the near future, the following deposits may be of practical interest: Berestovetskoye - Volynsky district of the Ukrainian SSR, Isachkovsky - Poltava district of the Ukrainian SSR, Mariupolsky - Mariupol district of the Ukrainian SSR, Chiaturskoye, Beloklyuchinskoye, Mangliskoye and Saganlugskoye, Adzharis-Tskhalskoye - Georgian SSR, Erivanskoye - Armenian SSR, as well as Olonets diabase from the shores of Lake Onega.

2. Properties of natural basalt. The direct use of natural basalt and its further processing presuppose sufficient knowledge of its mechanical, physical and chemical properties. However, these properties are significantly related to the composition and texture of basalt and therefore vary significantly depending on the deposit. If we talk about basalt in general, then its properties may be characterized only by the limits of the corresponding constants. The data given below for basalt are partly compared with data for diabase and gabbro. Apparent specific gravity (piece): 2.94-3.19 (B.), 3.00 (D.), 2.79-3.04 (G.). The true specific gravity (of the powder) is about 3.00 (B.). Porosity in % volume: 0.4-0.5 (B.), 0.2-1.2 (D.), 3.0 (G.). Water absorption: 0.2-0.4% by weight and 0.5-1.1% by volume (B.). The mass of 1 m 3 of dry basalt is about 3 tons. Compressive strength in kg/cm 2: 2000-3500 (B.), 1800-2700 (D.), 1000-1900 (G.). If the compressive strength of dry basalt is more than 3000, then wet basalt is more than 2500, and at a frost of 25° it is more than 2300. Wear strength (“hardness”, calculated by the formula: p = 20-w/3, where w is the mass, lost under normal conditions at 1000 revolutions of the abrasive disk) is characterized by numbers 18-19 (B., D., G.). Impact strength (“compactness”) when testing standardized samples: 6-30 (B., D.) and 8-22 (G.). Basalt is harder than steel. Young's modulus in (D cm -2)x10 -11 is equal to 11 (G.) and 9.5 (D.). The volumetric compression coefficient per 1 kg at a pressure of 2000 kg/cm2 is 0.0000018 (B.) and 0.0000012 (D.), and at a pressure of 10000 kg/cm2 it is 0.0000015 (B.) and 0.0000012 (D.). The melting of normal olivine basalt begins at a temperature of about 1150°, and the liquid-fusible state begins at a temperature of about 1200°. Molten rock ceases to flow when cooled to 1050°. More acidic rocks have a higher melting point, and it increases with silicic acid content. In particular, the basalt of the Adzharis-Tskhal deposit (dacitobasalt - according to Abikh or trachyandesite - according to new definitions) softens at 1180°, has the consistency of thick honey at 1260° and completely liquefies at 1315° (the author’s experiments in the materials science department of the SEI). Specific heat capacity of Syracuse basalt for different temperatures shown in the following table:

Heat of crystallization of basalt during the transition from an amorphous to a crystalline state 130 Cal. During crystallization, the volume decreases by 12% compared to the volume of basalt at a temperature of 1150°. The thermal conductivity of basalt in gram-calories is about 0.004. Coefficient of thermal expansion of basalt: 0.0000063 (at 20-100°), 0.000009 (at 100-200°) and 0.000012 (at 200-300°).

Chemically, basalts are resistant rocks: atmospheric agents, in Gary’s experiments, weathered from 1.5 to 0.8 mg/cm 2 of basalt over 18 months, while gray limestone lost 22.7 mg/cm 2 under the same conditions. The progress of the weathering process of basalt and diabase is presented in a comparative diagram (Fig. 2).

The number on the upper horizontal line shows the number of grams of weathered rock that must be taken so that it contains the same component corresponding to the designation of the horizontal line in question as this part is contained in 100 g of fresh rock. That. all points to the right of the vertical 100 mean depletion of the corresponding part, and those to the left mean enrichment. Consequently, during weathering, basalt is enriched in silica and alumina and depleted in alkalis, alkaline earths and iron in all forms, while diabase is enriched in oxide iron and sodium. This circumstance apparently speaks against diabase as an insulating material.

3. Basalt processing grounds. The properties of natural basalt make it an excellent building material, more reliable than granite. Basalt has been used for a long time. However, the extreme difficulty of processing basalt and dividing it into relatively narrow prisms forced us to come up with a special way of giving it geometric shapes.

It was natural to think about fusing this rock, since it itself is of fiery origin. But it is not enough to melt the basalt: upon rapid cooling, castings from it give a glassy mass, similar to natural hyalobasalts, brittle and technically inapplicable (Figs. 3 and 4).

The main task of basalt production is to restore the fine grain of melted basalt, the so-called regeneration (Fig. 5).

The idea of the possibility of remelting and restoring rocks to their original form arose in the 18th century. The Scot James Gall already in 1801 achieved the remelting of basalt and, in particular, established that basalt and lavas, being molten and quickly cooled, produce glass, while when they are slowly cooled, a rocky mass is obtained, with traces of a crystalline structure; This is the main position of the fiery processing of lava. Especially remarkable are the experiments of Scotsman Gregory Watt, who expanded the scale of smelting. Melting a block of basalt over 3 tons lasted 6 hours, and cooling under the cover of slowly burning coal required 8 days. Watt described the products of this slow cooling: on the surface - black glass; as you delve deeper into the frozen mass, grayish balls appear, grouped into bundles; then the structure is made radiant; still deeper, the substance is rocky and then granular in nature, and finally the mass is penetrated by crystalline plates. That. the possibility of melting and regenerating igneous rocks was discovered. But due to the lack of a sufficiently large demand for melted basalt for industry, the described experiments were forgotten. In 1806 Dobre and then in 1878 F. Fouquet and Michel Levy returned to the process of smelting and regeneration. They managed to reproduce almost all rocks of fiery origin and found out that this does not require either extreme temperatures or mysterious agents, but the whole point is to establish the proper melting and annealing regime. After cooling, the molten silicate turns into glass, the melting point of which is lower than the melting point of the original mineral. To restore the latter, it is necessary to anneal the glassy mass at a temperature exceeding the melting point of the vitreous body, but below the melting point of the crystalline mineral. The temperature range of these melting points is the region in which regeneration of silicate or aluminosilicate is possible; this interval may. quite insignificant. When we are talking not about one mineral, but about a set of 5-6 minerals that make up a crystalline rock, then the annealing mode would have to be set with a number of steps, and each mineral would have its own stop in the cooling process. However, in practice, these steps turn out to be so close to each other that we can limit ourselves to two stops. In relation to basalt, the first annealing, with red-white heat, gives crystallization of ferrous oxide and peridot, and the second, with cherry-red heat, crystallizes other minerals of the rock.

The first experiments in industrial smelting of basalt were undertaken in 1909 by Ribb, and various applications for fused basalt were found by engineer L. Dren. In 1913, for the industrial implementation of smelting processes, the Compagnie generate du Basalte was formed in Paris, and in Germany, Der Schmelzbasalt A.-G., in Linz on the Rhine; then both societies united under the common name “Schmelzbasalt A.-G.”, or “Le Basalte Fondu”. Currently in France there are two factories producing hl. arr. electrical and construction products, and in Germany - one serving the chemical industry.

4. Production of fused basalt. Withdrawal. The occurrence of basalt varies, and therefore its breaking is not always uniform. Slab-like basalt of covers or rocks is mined by blasting. Columnar basalt prisms can be separated using wedges and levers. Development is carried out in tiers, removing successive layers in rows of natural layers.

Splitting up . Broken basalt is stored outdoors. For smelting, it is crushed in Black or Gets crushers. Then the pieces are sorted by size, and the fines are used for concrete masses.

Remelting. Crushed basalt is fed into smelting furnaces, which use various heating methods. The most suitable furnaces are electric, gas (gas generating or with lighting gas) and furnaces with oil nozzles. The electric melting plant consists of a stationary electrode furnace and a mobile receiver on wheels, which serves to transport molten basalt throughout the casting workshop; this receiver also represents a small electrode furnace. Both types of furnaces are powered by two-phase current. The bottom of the furnace is made of refractory material and has a nozzle on the side for releasing the molten mass, from the receiver it descends into molds or molds for casting by simply tilting the receiver. In other furnaces, the throat is made inclined, so that loading the hearth and lowering the molten mass are a continuous process. The productivity of the described furnaces is from 3 to 50 tons per day. The Paris plant - a large-scale artisanal type - has 4 furnaces with a capacity of 80 kg each, operating continuously and heated by city gas; melting is carried out at 1350°. Another French plant, in Puy, runs on electric energy. Continuous production capacity is 8 tons per day.

Casting. Molten basalt is poured into molds or molds directly from the furnaces or taken to casting workshops. For casting, either sand trusses or steel molds are used. The former are much cheaper, but are not applicable in all cases, since the products come out matte and rough. Steel molds give products a shiny surface, but are relatively expensive. Careful casting results in a clean casting; otherwise, streaks and unevenness are visible, which in many cases do not, however, interfere with the use of the product.

Heat treatment. Almost immediately after casting, the products, still cherry-red, are removed from the molds and transferred to annealing hearth furnaces, similar to ordinary hardening furnaces. Depending on their purpose and size, the products are kept in the oven from several hours to several days. The initial annealing temperature is about 700°. The oven is sealed and cooled slowly; simmering in the oven lasts, depending on the size of the products and their required qualities, from several hours to 10-14 days. There are up to 35 such furnaces at the Paris plant.

Finishing. Once cooled, the products are ready for use. To give them the proper appearance, plaque is removed from them with steel brushes. If greater precision of planar edges is required, then finishing is done on wheels with a basalt base.

production cost. The production of fused basalt does not require either highly skilled labor or expensive equipment. The main costs of production in our conditions are the delivery of material, if it is brought from the Caucasus, and energy. When working with gas, 1 kg of finished basalt products requires about 900 Cal, i.e. about 1/4 - 1/3 m 3 of gas; When working with electrical energy, approximately 1 kWh is consumed per 1 kg of products. That. the cost of basalt products, for example, insulators, is significantly lower than porcelain. In France, the selling price of basalt insulators is 10-15% less than porcelain insulators, and for larger ones - 25-30%. The larger the products, the greater the price discrepancy between basalt and porcelain. However, there is reason to consider the above discrepancies in sales prices to be significantly understated due to the increase in profits of basalt production as a new business.

Production of fused basalt in the USSR. Having enormous technical and economic advantages and in some cases, such as the electrification of railways, being almost irreplaceable, the basalt industry has attracted the attention of technical and industrial circles. Experiments with the smelting of basalt and other rocks, undertaken on behalf of the Glaelectro VSNKh in the materials science department of the SEI and then in the State Electrical Technique, experiments with the smelting of diabase in the Mining and Metallurgical Laboratory and the interest of the Supreme Economic Council of Georgia and Armenia in this industry can be considered harbingers of the rapid development of the basalt business. From an economic point of view, b. a very advantageous natural combination of favorable factors was noted: the possibility of basalt mining very often coincides geographically with the availability of sources of hydroelectric energy for its processing, i.e. with a regional power plant, which requires basalt insulators, and with centers of electrochemical production, which require fire and acid-resistant basalt equipment. The indicated coincidence, in connection with the profitability of small basalt plants and the comparative high cost of transport, gives reason to foresee in the future a network of small basalt plants throughout the country.

5. Properties of processed basalt. Remelted and reclaimed basalt generally has the properties of natural basalt, but in an improved form (see Figs. 3 and 5).

Mechanical properties: a) compressive strength - about 3000 kg/cm 2 ; b) wear resistance, tested using a Derry mill powdered with sand, averaged 0.9 mm after 1000 revolutions; c) having high viscosity, basalt does not break easily, and basalt insulators and other products can practically be considered unbreakable. Compared to porcelain, basalt is 2-4 times less fragile; different values of this quantity depend on the annealing mode; presence of impurities fragility m. very elevated; d) tensile strength was tested on basalt supports for the third bus of electric railways. etc., and for comparison, the same sandstone supports were tested; rupture of basalt products was observed at 3700-4700 kg, and rupture of the same sandstone products - at 1200 kg.

Thermal properties: a) melted basalt resists temperature changes, even sudden ones; a basalt plate 8 mm thick, immersed alternately in boiling and cold water, did not show any signs of cracking; insulators exposed to the sun and then exposed to thunderstorms, as well as insulators tested according to the rules of the French Union of Electrical Syndicates (sudden transfer from water at 65° to water at 14°), showed no change in electrical properties; the upper limit of the thermal interval can be further increased; b) at the moment of hardening, basalt allows for stamping or other introduction of iron parts of any volume into it and firmly adheres to them, without requiring cementation; c) basalt withstands significant heating without showing ruptures, cracks, “fatigue” or “aging”; d) due to its low thermal conductivity, basalt can serve as a thermal insulator.

Hygroscopicity. Being quite compact and covered with an autogenous glaze, basalt is completely waterproof and non-hygroscopic.

Electrical properties: a) basalt has a significant electrical strength: for bridge basalt it turned out to be about 32 kV/cm with a plate thickness of 18 mm, and for special electrical basalt, both heat-treated and vitrified, it was from 57 to 62 kV/cm at the same thickness; b) when a breakdown occurs and a powerful arc is formed, the basalt insulator is still not damaged by this, because after the arc stops, the breakdown site disappears and the insulator is healed without a trace; c) basalt insulators, when processed, are automatically covered with a glass-like basalt glaze 1.5-2 mm thick, gradually turning inwards to granular basalt; this glaze provides an excellent barrier to surface electrical leaks and protects insulators and other products from hygroscopicity and the action of atmospheric agents; Having a composition identical to the composition of the insulator itself, the glaze adheres to it as a homogeneous body and therefore is not in danger of cracking or peeling. In addition, if this glaze is violently damaged, a substance of the same composition is exposed, so that the specified damage is not fatal for the insulator.

Chemical properties. Chemically, basalt products, according to French information, are very resistant; in table Table 1 provides data on the effect of various reagents on processed basalt.

Data from further tests are given in table. 2.

Appearance . Remelted but unannealed basalt resembles glass: it has a shiny fracture, brown-black color and is fragile. After annealing, the remelted basalt acquires a black or dark color, matte fine-grained fracture and the toughness of natural rock. The external appearance of the products depends on the material of the mold and mold (see paragraph 4).

So, in terms of mechanical strength, thermal and chemical resistance, high and unique electrical properties, low cost and relatively easy workability, processed basalt should be recognized as one of the most remarkable electrical engineering materials.

6. Use of recycled basalt. The basalt industry is still too young to be able to anticipate all the uses of the new material at present. So far, the following have emerged: a) in networks of high currents of high and low voltage - linear insulators in the open air (Fig. 6),

support insulators, insulators of the third bus of electrical railways. d. and subways (Fig. 7), high voltage output insulators;

b) in low current networks and in radio communications - telegraph and telephone insulators, pull-out insulators and other insulating parts for antennas; c) in the electrochemical industry - insulating stands for batteries, dishes, bathtubs, etc.; d) in the general chemical industry - acid-resistant equipment, including all kinds of dishes, baths, taps, propellers, etc., equipment for temperatures up to 1000°; e) in construction - insulating bridges (Fig. 8), bridges, stair steps, wall and floor cladding, especially when there are acidic fumes, etc.

Line insulators. In view of the exceptional interest represented by basalt in electrical engineering, we present test data at the Paris Central Electrical Laboratory of ten insulators with iron pins embedded in them, and five of them were previously subjected to a thermal test (see paragraph 5). During a dry test, the first sparks sliding along the insulator appeared at 32.5-38 kV, the arc formed at 35-43 kV, the breakdown of the skirt was obtained at 40 kV, and the neck - at 37.5-39.5 kV. A wet test under artificial rain produced an arc at 18-20 kV, after which after 30 sec. the insulator was breaking through. The test under oil established the breakdown voltage at 35-58 kV. Testing of pull-out insulators with alternating voltage, which was raised until breakdown and then, immediately after breakdown, began to be raised again until a new breakdown, and so on 4 times, gave the results presented in table. 3.

Telegraph type insulators. By testing high-current basalt insulators, similar in type to telegraph ones, carried out at the Moscow Scientific Testing Telegraph Station, the surface electrical resistance of basalt insulators was found to be significantly higher than that of the corresponding porcelain ones; but when tested in the rain, the resistance of basalt recovered somewhat more slowly than that of porcelain. This probably depended on the rough surface of the high-current insulators tested, for which telegraphy requirements were not taken into account.

7. Other uses of basalt. In addition to the use of natural basalt as a building material and crushed stone, and the use of thermally processed basalt in various industries, basalt and related rocks are also used as a component in ceramic and glass production. Thus, Borjomi andesite has been used for several years in making glass for bottles for Borjomi mineral water, giving it strength and a dark color. The English Wedgwood porcelain factory has long been producing pottery with black, unglazed and easily polished shards, the so-called. “basalt” (Basalt) or “Egyptian” (Egyptian), - the mass for it contains basalt.

Basalt is the most common igneous mountain natural mineral; it is obtained from volcanic rocks; after an eruption occurs, its temperature can reach several 1000 °C.

The stone is quickly recognizable, as it can be dark, black, gray-black, or smoky. Most often it has the following appearance: a dark heavy mass, where small light rectangles of feldspar and bottle-green eyes of olivine are visible. The mineral is very hard, has a high density of 2530-2970 kg/m2, high temperature melting, varying between 1100-1250 °C,

Under natural conditions, the stone can be seen in the form of streams emanating from an avalanche that appears during the eruption process through existing volcanic cracks. There are several types of this stone: some contain olivine, others do not - they are called tholeiitic containing particles of quartz. Stones containing olivine can be found on the Pacific islands.

Deposits of the mineral were discovered in India and America. Many stones are found in the Italian volcanoes Vesuvius and Etna. Today the stone is mined in Kamchatka, Ireland, Scotland and Iceland. You can also find traces of them in Ukraine.

Basalt - properties and its wide application

The stone contains: volcanic glasses, microlites, titanomagnetite, magnetites and also clinopyroxene. The mineral has a porous, glassy and latent crystalline aphyric structure.

Properties that it has basalt, characterize it as the most reliable and protective element for facing work. The stone has the following properties:

- fire resistance;

- strength;

- durability;

- soundproofing;

- thermal insulation;

- environmental cleanliness.

It contains augite, calcium feldspar and its varieties. Sometimes an admixture of olivine is found.

Thanks to the mineral, high-quality additives for crushed stone and strong fibers are made, from which heat-insulating and sound-proofing materials are made. Mainly used to create high-quality slabs.

Stone is widely used in the construction field in the form of facing materials; it is used to make sculptures and various statues, and it is also used for the exterior decoration of most buildings. The stone has an unusual property, it can withstand both high and low temperatures, and therefore it is widely used outdoors.

Cladding made from this stone, creates a beautiful appearance of any building. It will remain the same for many years as the day it was installed. Its service life spans many decades. It is easy to install; no ties or other reinforcements are needed. The stone itself has excellent characteristics that allow you to enjoy the environmental friendliness and durability of the material used and the masterpieces created with its help.

From large quantity available slabs, most often slabs containing basalt. They have high strength and are easy to cut and saw. The most complex and serious structures are built from them. These slabs are environmentally friendly and do not place a large load on the foundation.

Plates made from this mineral effectively regulate and absorb high level noise in residential buildings and other public spaces.

The mineral has a wide range of useful properties that can not only improve the appearance, but also prevent adverse consequences after construction has been completed and further operation has begun. Noise and sound insulation properties make it possible to ensure good conditions for living in residential buildings.

The rock of this mineral has high fire resistance, can withstand temperatures above 1500 degrees Celsius and is used in the form of fire protection. Minerals can resist the action of alkalis, acids, paints, and have high abrasion resistance. Serves as an indispensable natural filler for creating concrete blocks.

The main criterion is still the environmental friendliness of this mineral. When molten, the mineral is used to create steps, stairs, tiles and other building materials. Stone powders are used for the manufacture of reinforced and pressed products.

The black color of the mineral interacts wonderfully with silver. They make unusual things out of it jewelry, which are a great addition to evening dresses. Light shades of stone are used to make luxurious bracelets, beads, belts, necklaces, and various sets.

Basalt – basic origin and process of change

Basalt is obtained as a result of the melting of rocks such as lherzolites, harzburgites, wehrlites. The basic composition is determined by the chemical and mineral compounds that contain the protolite and maintain its degree of melting.

The following types of minerals are available:

- oceanic ridges;

- continental;

- intraslab.

This type of stone is easily changed as a result of hydrothermal processes. Particularly visible are the changes in the stones that pour out at the bottom of the seas and oceans. They energetically combine with water, and many useful components are released and deposited.

During the process of metamorphism, stones can turn into greenschists, it all depends on the conditions. And if pressure is put on them, they can generally take on a bluish color.